Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

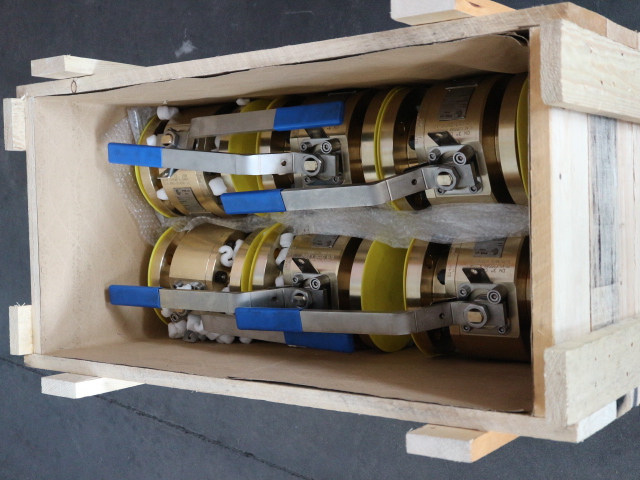

Floating Ball valve DN1/2" #300 RF

Floating Ball valve DN1/2" #300 RF

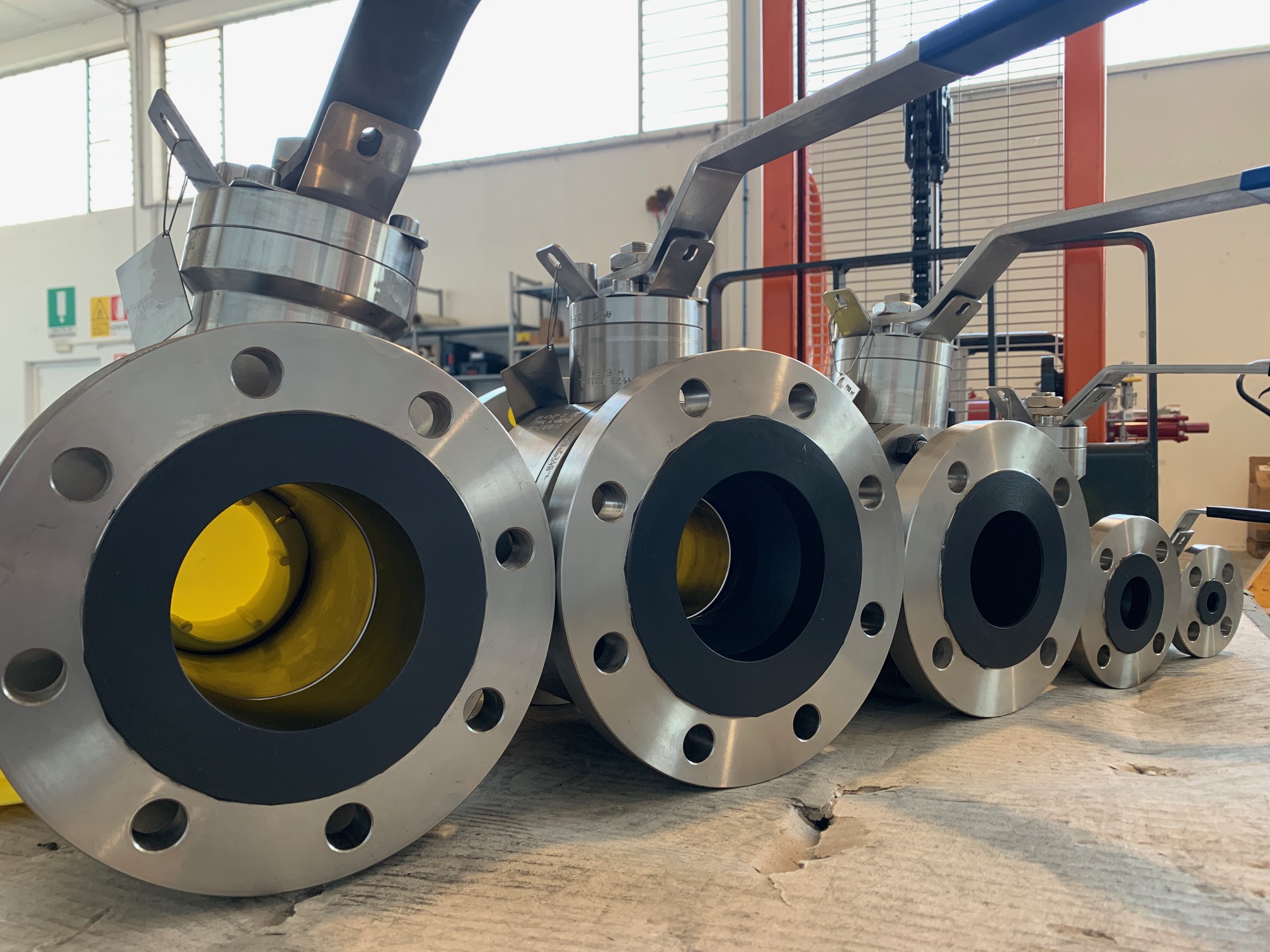

Trunnion Ball valve DN12 #150 RF

Trunnion Ball valve DN12 #150 RF

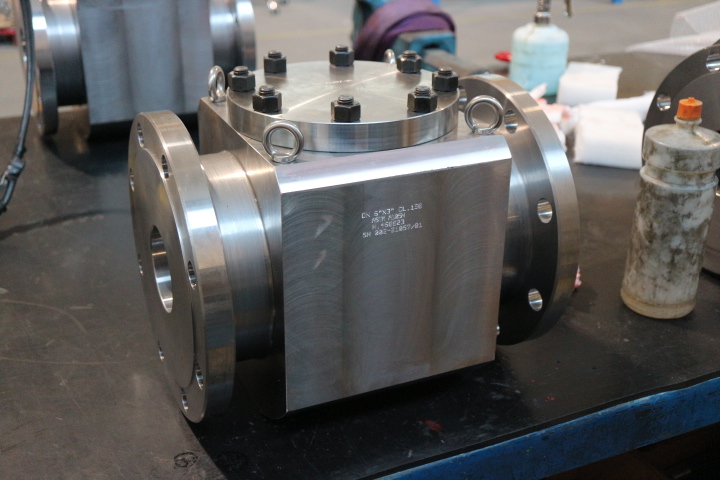

Trunnion Ball valve DBB DN3 #1500

Trunnion Ball valve DBB DN3 #1500

Trunnion Ball valve DBB DN2 #2500

Trunnion Ball valve DBB DN2 #2500

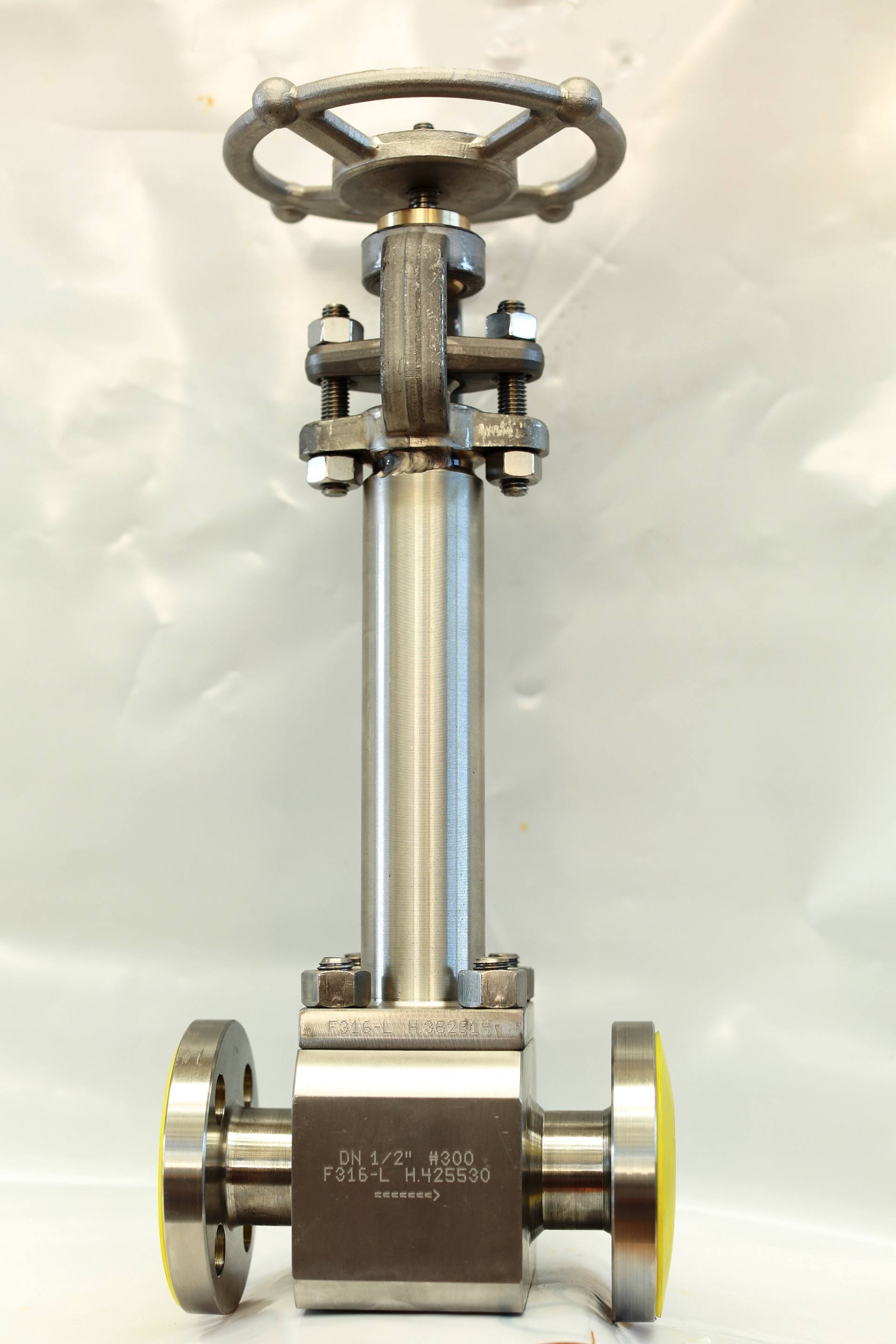

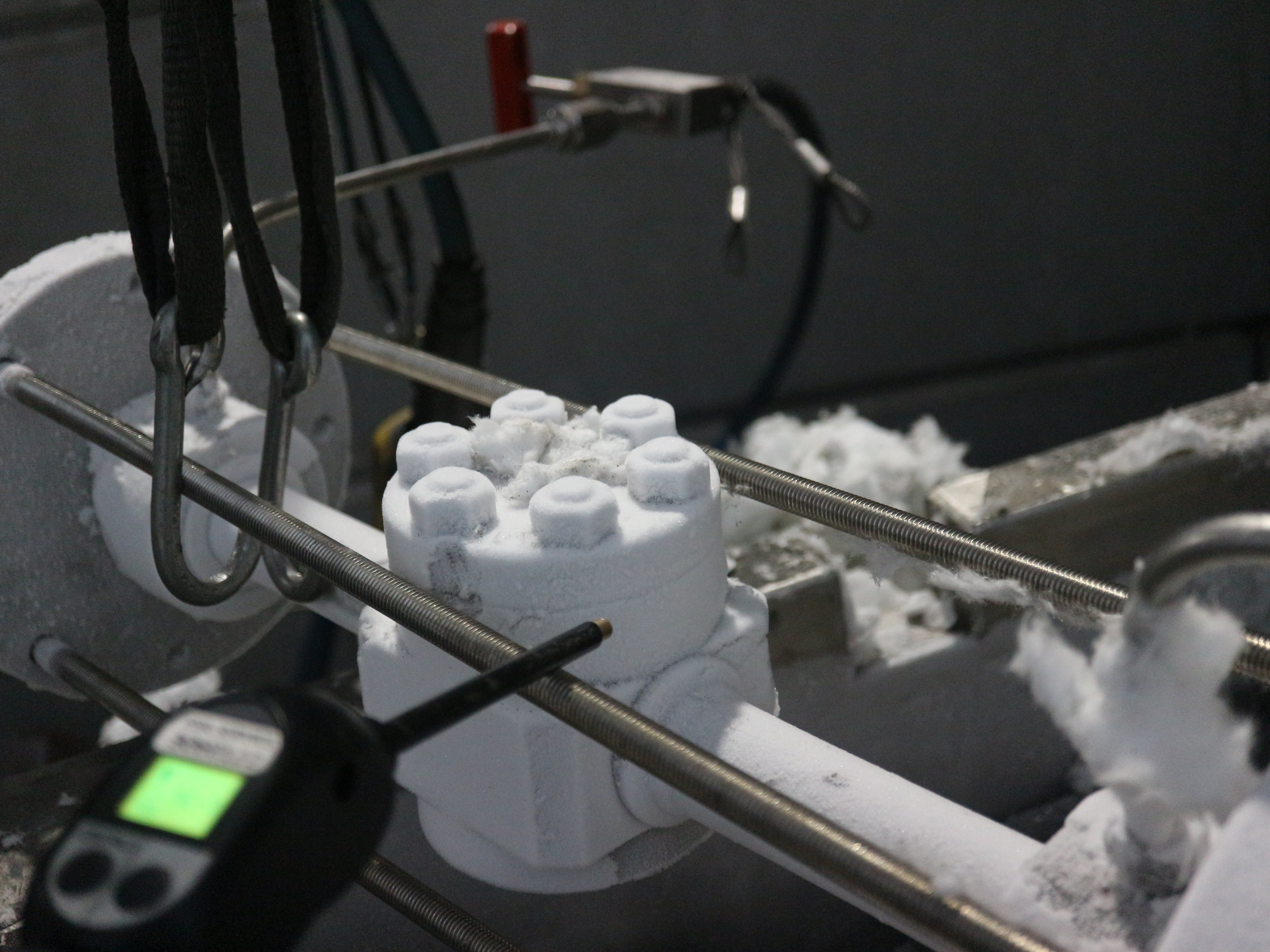

Trunnion Ball valve DN2 #150 Cryo

Trunnion Ball valve DN2 #150 Cryo

Floating Ball valve DN4 #150 Bronze-Aluminium

Floating Ball valve DN4 #150 Bronze-Aluminium

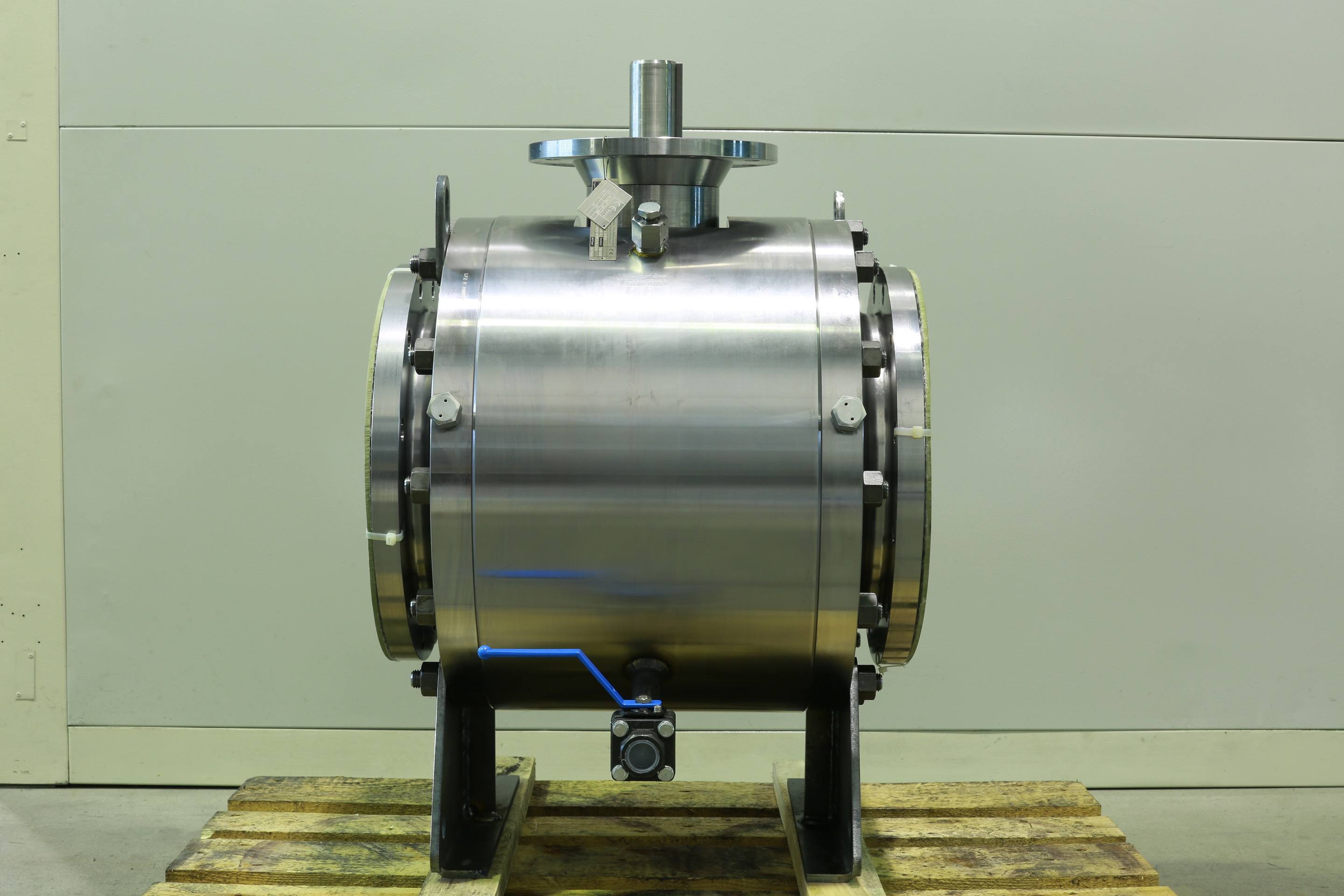

Trunnion Ball valve DN12 #900

Trunnion Ball valve DN12 #900

Floating Ball valve PFA lined and FET packing on stem

Floating Ball valve PFA lined and FET packing on stem

Top Entry Ball valve DN 8 #600 Cryo

Top Entry Ball valve DN 8 #600 Cryo

Applicable Standards:

Material:

Type and standard connections:

Pressure rating:

Size range:

Design Features:

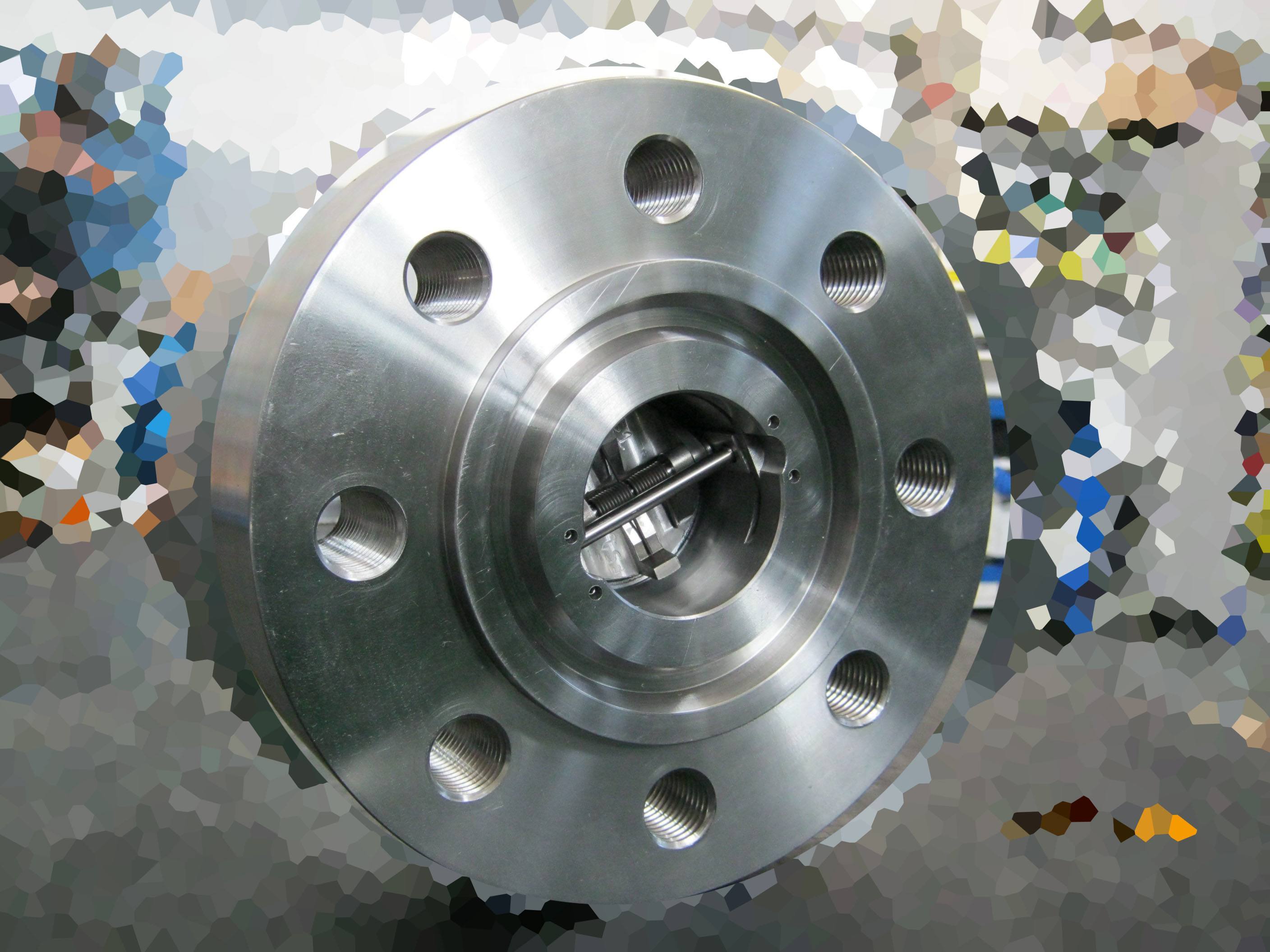

Dual Plate Check valve

Dual Plate Check valve

Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

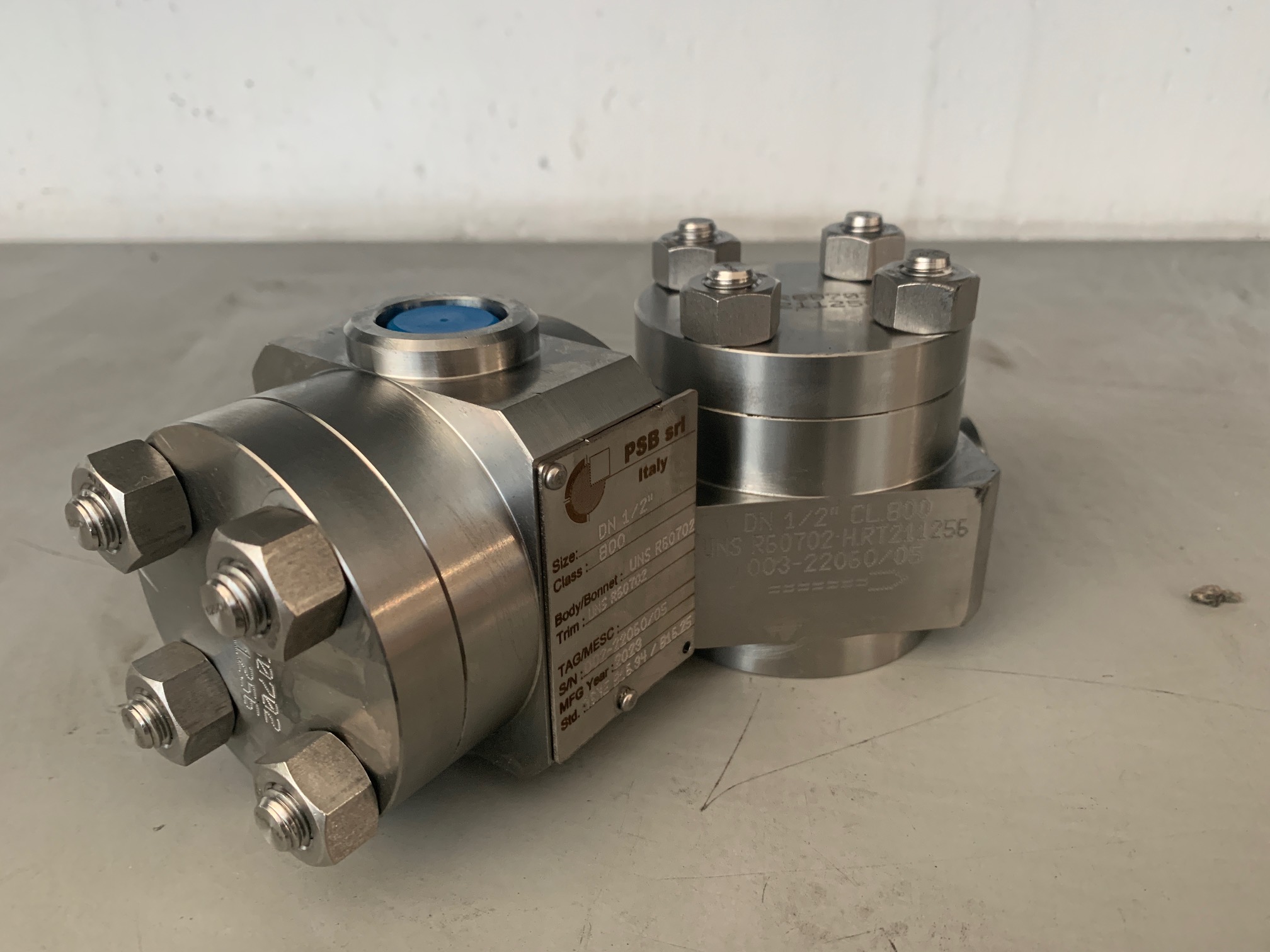

Gate and Globe valve DN 15 #800 - Hastelloy B3 UNS R60702

Gate and Globe valve DN 15 #800 - Hastelloy B3 UNS R60702

Gate valve DN 1 and 1_1-2 #1500-#2500 BW Welded Bonnet

Gate valve DN 1 and 1_1-2 #1500-#2500 BW Welded Bonnet

Gate and Globe valve DN 15 #800 - Hastelloy B3 UNS R60702

Gate and Globe valve DN 15 #800 - Hastelloy B3 UNS R60702

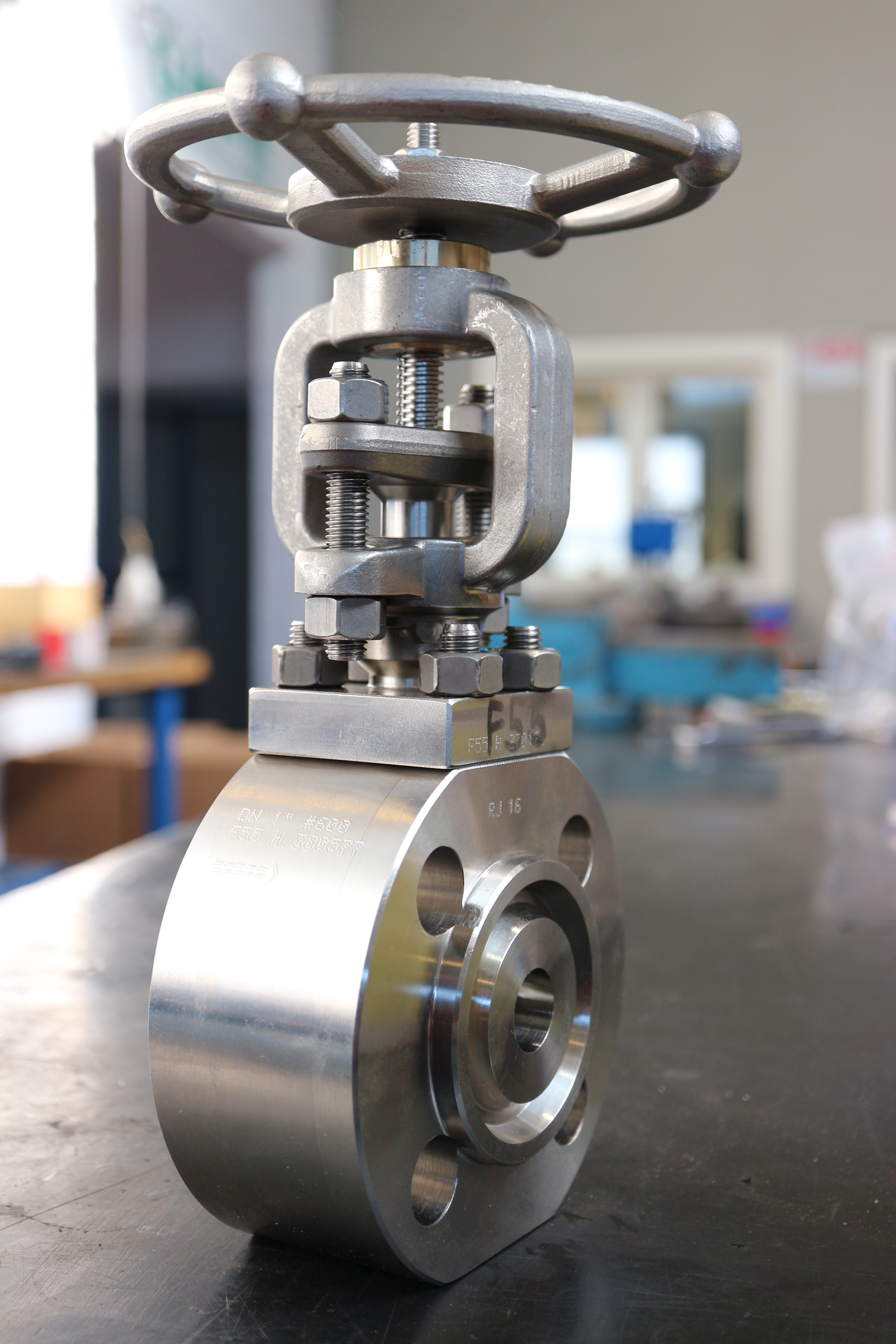

Gate valve Pressure Seal DN 2 #2500 BW - Inconel 825

Gate valve Pressure Seal DN 2 #2500 BW - Inconel 825

Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

Globe valve Bellow seal DN 2 #300 - Bare Stem

Globe valve Bellow seal DN 2 #300 - Bare Stem

Globe valve BB DN 15 #300 - Cryogenic type

Globe valve BB DN 15 #300 - Cryogenic type

Globe Valve DN1 PN400 - SASOL Specification (painted)

Globe Valve DN1 PN400 - SASOL Specification (painted)

Globe Valve DN1 PN400 - SASOL Specification

Globe Valve DN1 PN400 - SASOL Specification

Globe valve BB DN2 #150 - Dead-Man

Globe valve BB DN2 #150 - Dead-Man

Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

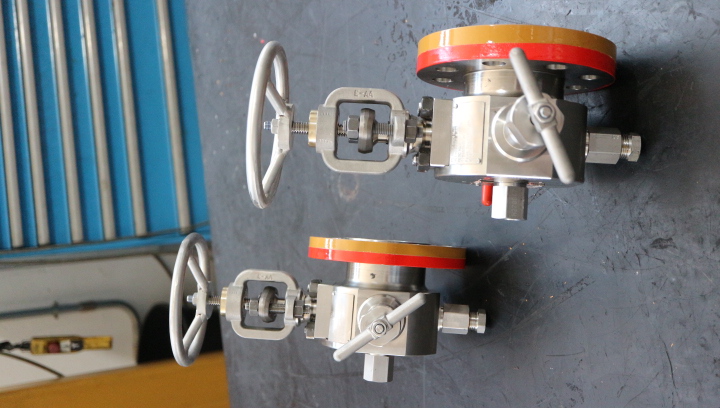

Monoflange valve DBB DN 2 #300 for -50 °C - SHELL MESC

Monoflange valve DBB DN 2 #300 for -50 °C - SHELL MESC

Monoflange valve SB DN1 #1500

Monoflange valve SB DN1 #1500

Monoflange valve DBB DN2 #10K - KPO project

Monoflange valve DBB DN2 #10K - KPO project

Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

Piston Check valve DN1 PN400 - SASOL specification

Piston Check valve DN1 PN400 - SASOL specification

Piston Check valve DN1 PN400 - SASOL specification (painted)

Piston Check valve DN1 PN400 - SASOL specification (painted)

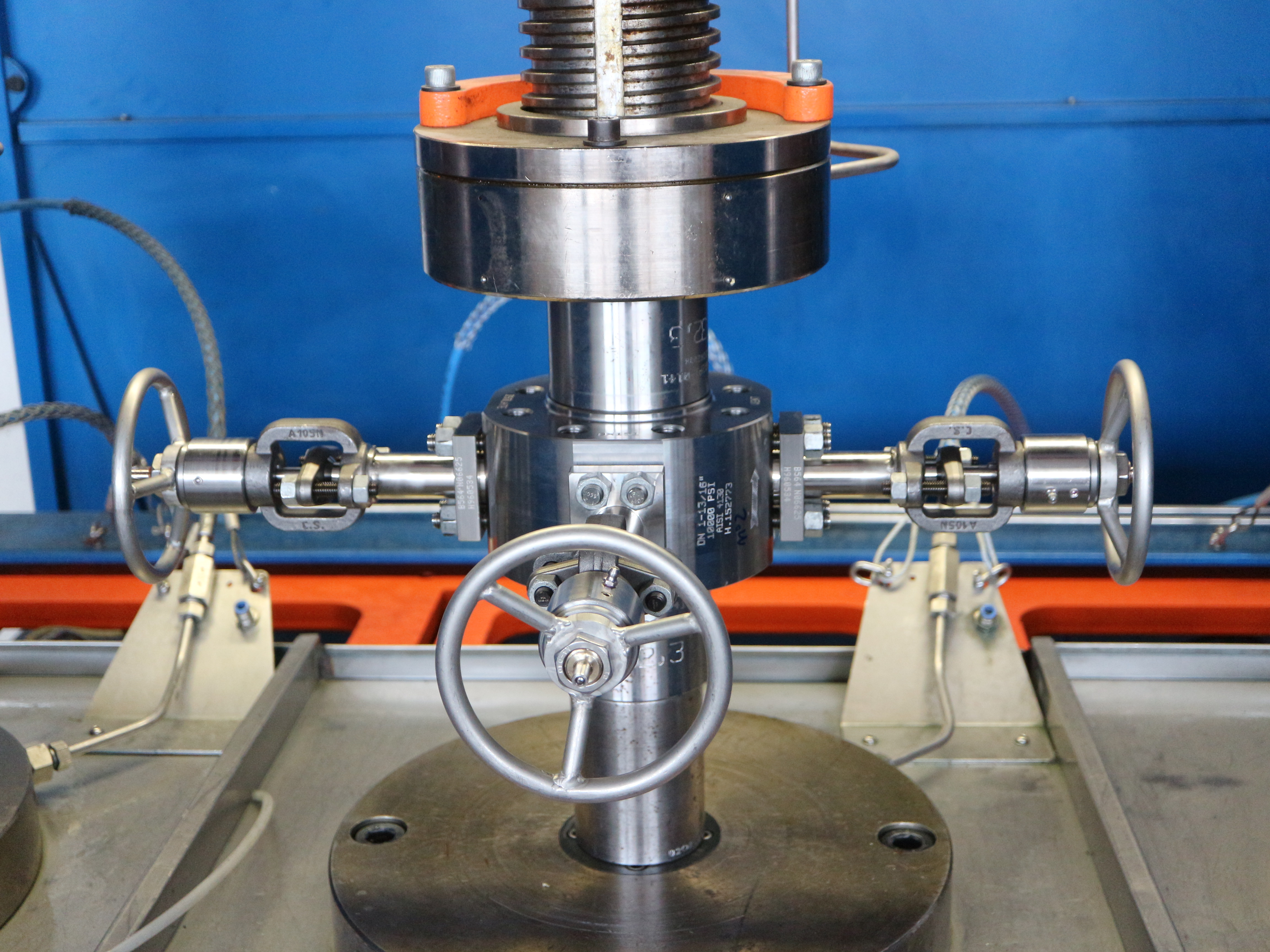

Piston Check valve DN2 PN400 - specification (during hydro test)

Piston Check valve DN2 PN400 - specification (during hydro test)

Piston Check valve BB DN1 #1500 with pups (cryo tested)

Piston Check valve BB DN1 #1500 with pups (cryo tested)

Piston Check valve DN15 #800 SW - UNS R60702

Piston Check valve DN15 #800 SW - UNS R60702

Piston Check valve DN15 #800 SW - UNS R60702

Piston Check valve DN15 #800 SW - UNS R60702

Applicable Standards:

Material:

Standard end connections:

Pressure rating:

Size range:

Design Features:

Swing Check valve DN 6 #150 + Jacket (1)

Swing Check valve DN 6 #150 + Jacket (1)

Swing Check valve DN 6 #150 + Jacket (2)

Swing Check valve DN 6 #150 + Jacket (2)